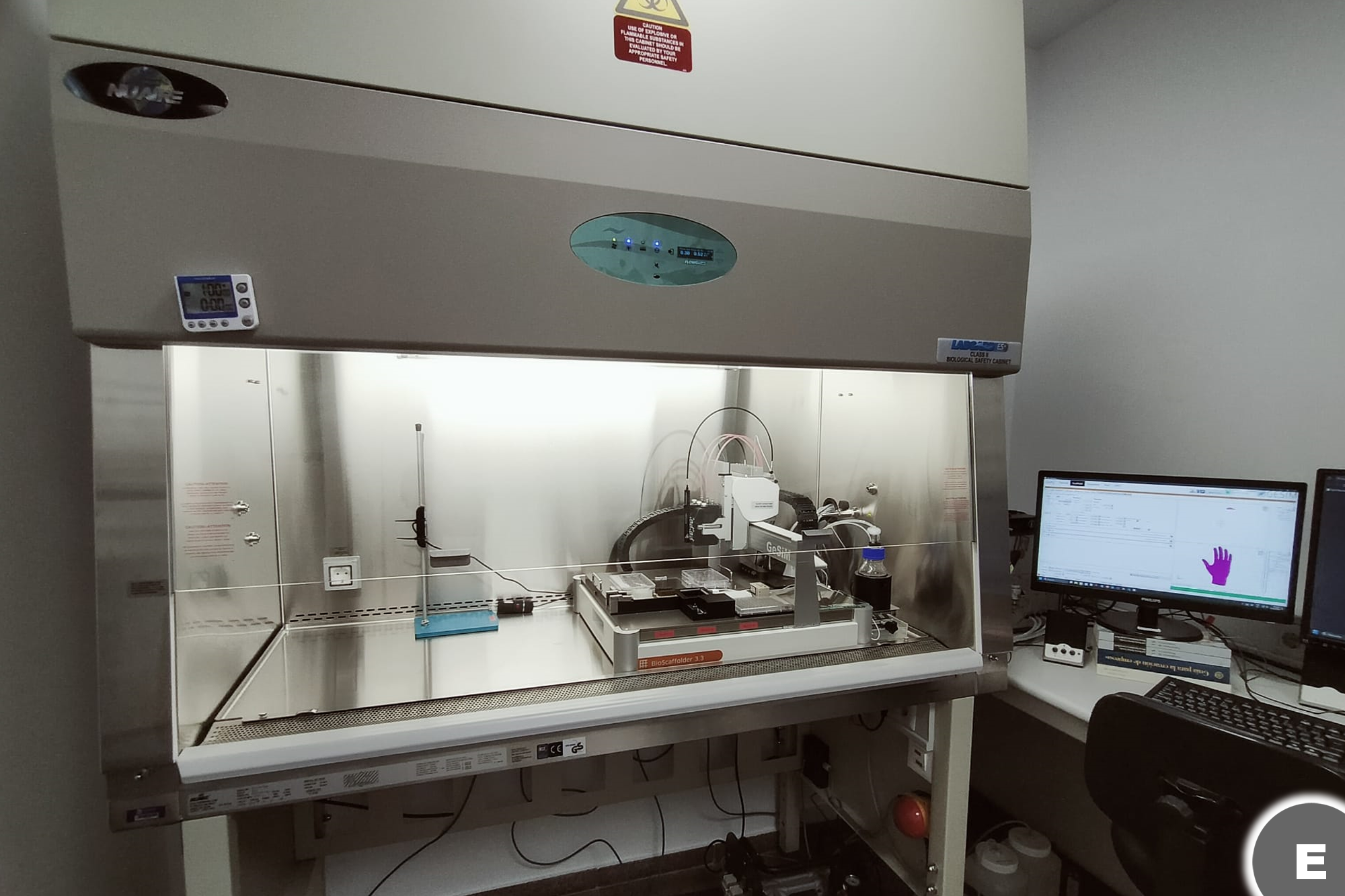

GeSIM 3D Bioprinter (BS3.3 GeSiM)

The bioprinter is a versatile equipment designed to tackle current problems in cutting-edge research fields and, therefore, it has many tools that allow extruding a huge range of polymers such as those employed in tissue engineering. A high flexibility and compact dimensions are combined so it could be used in biological safety cabinets and sterile environments.

A cartesian robotized platform controls the movement of the bioprinter in X, Y and Z axes. In the horizontal XY-plane it has a range of 385 mm x 265 mm with micrometric precision. Several tools are located in four independent Z-axes at the same time with a range of 100 mm.

In the first 3 Z-axes different holders are located for pneumatic extrusion. Several adaptors make possible to use 10 and 30 mL cartridges with nozzles whose diameters range from 250 to 840 µm. Besides, a peltier module is available to regulate temperature from 4 to 80°C in a metallic cartridge with nozzle diameters from 150 to 330 µm. In addition, another adapter allows housing a 50 mL syringe driven by a step motor. A core/shell extruder for coaxial printing of two materials and a 365 nm UV-LED pen are also available.

The fourth Z-axis holds a Z-sensor and a piezoelectric pipet. The former measures the height of the printing points and the latter, which is pneumatically controlled, transfers small liquid sample amounts, around 300 pL droplets, from multi-well plates to a defined location with a frequency of around 1000 droplets per second.

The equipment also has several accessories to facilitate the extrusion such as stroboscopic light to measure the diameter of the nozzles or the shape and size of the piezoelectric pipet droplets, a wash station and a dry pad also for the pipet, or cleaning brushes ant a tip cleaner for the plastic or metallic nozzles. On top of that, other accessories might be available increasing the potential of the equipment.

The great versatility of this bioprinter, its modular configuration and the huge range of tools and accessories which are available, make it essential in a big amount of applications like printing different (bio-)polymers which might contain cells, the design or manufacturing of multi-material scaffolds for tissue engineering, organoid printing, co-printing of hard and soft biopolymers, functionalization of metal implants with soft polymer layers, etcetera.

This equipment has been acquired thanks to an intervention co-financiated by the European Union through the Programa Operativo del Fondo Europeo de Desarrollo Regional (FEDER) from the Comunitat Valenciana 2014-2020 (PROYECTO: IDIFEDER2020/022).

Contact: Enrique Rodríguez (e-mail: ; phone:+34 965 22 2237).